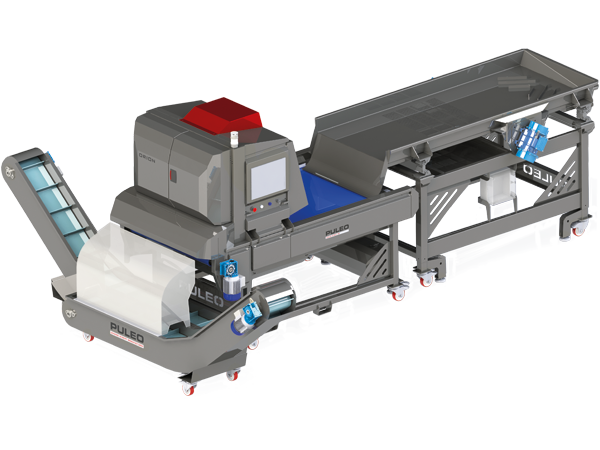

The system consists of two parts:

- AISI 304 stainless steel vibrating table with special wings for more even distribution of the product across its entire width. Equipped with a draining section and stainless steel chute to ensure speed and stability of the product on the sorting belt.

- PVC belt for high-speed product sorting, with an analysis and identification block with linear camera (data are processed in real time).

models

| ORION SELECTO | Selezionatore/Sorter: 1,65 kW - Tavolo vibrante dosatore/Vibrating dosing table: 0,95 kW | 1-15 tons/h | 1680 mm | 2180 mm | 5370 mm |

| ORION SELECTO | |

|---|---|

| Selezionatore/Sorter: 1,65 kW - Tavolo vibrante dosatore/Vibrating dosing table: 0,95 kW | |

| 1-15 tons/h | |

| 1680 mm | |

| 2180 mm | |

| 5370 mm | |

Nome del modello

Potenza del motore

Produzione oraria

Larghezza (mm)

Altezza (mm)

Lunghezza (mm)

Dimensione porta (mm)

Potenza installata - giri

Capacità Tank (L)

Capacità vaschetta mosto (L)

Superficie refrigerante

Adatto per diraspatrici da:

Uva intera (kg)

Uva diraspata (kg)

Vinacce fermentate (kg)

Attacco mandata (mm)

Da abbinare a

Altezza scarico regolabile (mm)

Pressione (bar)

Main features

- Product feed by means of a belt made of food-grade PVC with stabilising pegs. Speed regulation by inverter.

- Closed selection compartment with LED bars for lighting the analysis area.

- Self-learning system of the product to be analysed with possibility of modification/ calibration during product unloading.

- Adaptability to any type of berry product (grapes, berries, blueberries, currants, etc.).

- Counter-rotating washing brushes with dosing nozzles for high-pressure water injection, allowing appropriate cleaning.

- User-friendly user interface with colour touch screen display.

Optical selection is based on two factors:

– 1 Shape

– 2 Colour

For any type of product transferred onto the belt, the camera will first identify its shape and if its suitability is confirmed, the processor will give its consent to continue with the subsequent colour examination. Should the shape or colour prove to be unsuitable, the system, via a special I/O card, will drive the compressed air electrovalves giving the ejection command.