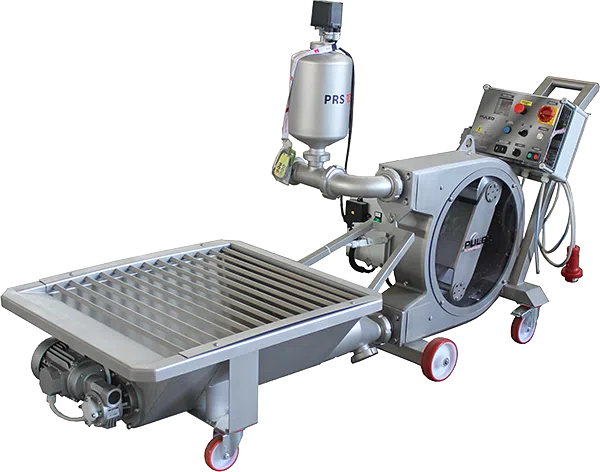

Ideal for transferring liquid or quite dense products in a soft and delicate way.

Thanks to gentle process, the product does not suffer concussions thus avoiding its organoleptic alteration.

Compensation chambers are made of stainless steel, Inner Pipe is made of EPDM alimentary rubber.

Equipped with inverter (frequency variant) to regulate pump capacity and with pressure switch, that automatically stops the pump in case of increasing delivery pressure.

| PRS 4 | 1.1 kW | 25-70 Rpm | 1,5-4 m3/h | / | DIN 40 | 3 bar |

| PRS 7 | 1.5 kW | 25-70 Rpm | 2,5-7 m3/h | 1,7-4,9 ton/h | DIN 50 | 3 bar |

| PRS 12 | 3.00 kW | 25-70 Rpm | 4,5-12 m3/h | 3-8,4 tons/h | DIN 65 | 3 bar |

| PRS 18 | 4.00 kW | 20-60 Rpm | 7-20 m3/h | 4,9-14 tons/h | DIN 80 | 3 bar |

| PRS 26 | 5.5 kW | 25-70 Rpm | 10-30 m3/h | 7-21 tons/h | DIN 80 | 3 bar |

| PRS 4 | |

|---|---|

| 1.1 kW | |

| 25-70 Rpm | |

| 1,5-4 m3/h | |

| / | |

| DIN 40 | |

| 3 bar | |

| PRS 7 | |

|---|---|

| 1.5 kW | |

| 25-70 Rpm | |

| 2,5-7 m3/h | |

| 1,7-4,9 ton/h | |

| DIN 50 | |

| 3 bar | |

| PRS 12 | |

|---|---|

| 3.00 kW | |

| 25-70 Rpm | |

| 4,5-12 m3/h | |

| 3-8,4 tons/h | |

| DIN 65 | |

| 3 bar | |

| PRS 18 | |

|---|---|

| 4.00 kW | |

| 20-60 Rpm | |

| 7-20 m3/h | |

| 4,9-14 tons/h | |

| DIN 80 | |

| 3 bar | |

| PRS 26 | |

|---|---|

| 5.5 kW | |

| 25-70 Rpm | |

| 10-30 m3/h | |

| 7-21 tons/h | |

| DIN 80 | |

| 3 bar | |

Peristalsis principle is applied to these pumps, according to which the prevalence of the processed fluid is impressed by a progressive compression produced by rollers that run along the inner pipe.

The alternation between compression and relaxation of the tubular element, produced by the rollers, generates the fluid sucking and its push in the pressure line.

- Priming up to 9 meters deep.

- They can run dry.

- They allow a reversible flow.

- Loading hopper.

- Level control.

- Cooling type motor.

- Radio or telecontroller.