Pressing has the purpose of extracting the juice from wholes or crushed grapes in the white winemaking process, or the must-wine or wine from fermented grapes after racking in the red winemaking process.

This process must preserve the integrity of the solid parts of grapes, prevent the breakage of pips, the lacerations of stalks, when dealing with non-destemmed grapes, and prevent oxidation.

Closed tank pneumatic Presses carry out the pressing process inside a horizontal cylinder thanks to a membrane, made of top grade alimentary PVC material, pushing against a large wall of longitudinal holed gutters that allow draining.

Mainly designed for the soft pressing of grapes and for the extraction of high quality must, Puleo’s new Pneumatic Presses introduce a long series of standard upgrades.

| C8 | 1275 mm | 1840 mm | 2400 mm | 525X425 mm | 720 l | 150 l | / | 400/600 Kg | 1300/1800 Kg | 1850/2400 Kg | |

| C16 | 1725 mm | 2300 mm | 3200 mm | 460X360 mm | 1670 l | 300 l | 3,5 mq | 1000/1300 Kg | 3000/4200 Kg | 4200/5700 Kg | |

| C22 | 1725 mm | 2300 mm | 3700 mm | 460X360 mm | 2170 l | 400 l | 4 mq | 1300/1700 Kg | 4000/5500 Kg | 5500/7600 Kg | |

| C30 | 1950 mm | 2520 mm | 4100 mm | 500X420 mm | 3100 l | 400 l | 4 mq | 1900/2500Kg | 5800/7900Kg | 8000/11000 Kg | |

| C40 | 2060 mm | 2620 mm | 4150 mm | 500X420 mm | 3960 l | 350 l | 4,5 mq | 2400/3200 Kg | 7500/10000 Kg | 10500/14000 Kg | |

| C50 | 2060 mm | 2620 mm | 4650 mm | 600X450 mm | 4800 l | 400 l | 5,5 mq | 2900/3900 Kg | 9100/12000 Kg | 12500/17000 Kg | |

| C70 | 2060 mm | 2310 mm | 5900 mm | 600X450 mm | 6800 l | 700 l | 8 mq | 4100/5400 Kg | 13000/17700 Kg | 18000/25000 Kg | |

| C80 | 2060 mm | 2360 mm | 5900 mm | 800X580 mm | 7940 l | 700 l | 9 mq | 4800/6300 Kg | 15200/20700 Kg | 21000/29200 Kg | |

| C100 | 2060 mm | 2360 mm | 6000 mm | 800X580 mm | 9480 l | 500 l | 10 mq | 5700/7600 Kg | 18500/25500 Kg | 26000/35000 Kg | |

| C150 | 2600 mm | 2640 mm | 6700 mm | 800X580 mm | 14950 l | 500 l | 12 mq | 9000/12000 Kg | 29000/42000 Kg | 43000/57000 Kg | |

| C250 | 2900 mm | 2720 mm | 9900 mm | 800X580 mm | 24700 l | 750 l | 17 mq | 14800/19800 Kg | 49000/75000 Kg | 77000/94000 Kg | |

| C320 | 2850 mm | 2720 mm | 10100 mm | 800X580 mm | 32100 l | 700 l | 17 mq | 19300/25700 Kg | 64000/100000 Kg | 101000/125000 Kg | |

| C440 | 3200 mm | 3000 mm | 11400 mm | 800X580 mm | 44200 l | 700 l | 17 mq | 26500/35400 Kg | 89000/138500 Kg | 139000/172000 Kg |

| C8 | |

|---|---|

| 1275 mm | |

| 1840 mm | |

| 2400 mm | |

| 525X425 mm | |

| 720 l | |

| 150 l | |

| / | |

| 400/600 Kg | |

| 1300/1800 Kg | |

| 1850/2400 Kg | |

| C16 | |

|---|---|

| 1725 mm | |

| 2300 mm | |

| 3200 mm | |

| 460X360 mm | |

| 1670 l | |

| 300 l | |

| 3,5 mq | |

| 1000/1300 Kg | |

| 3000/4200 Kg | |

| 4200/5700 Kg | |

| C22 | |

|---|---|

| 1725 mm | |

| 2300 mm | |

| 3700 mm | |

| 460X360 mm | |

| 2170 l | |

| 400 l | |

| 4 mq | |

| 1300/1700 Kg | |

| 4000/5500 Kg | |

| 5500/7600 Kg | |

| C30 | |

|---|---|

| 1950 mm | |

| 2520 mm | |

| 4100 mm | |

| 500X420 mm | |

| 3100 l | |

| 400 l | |

| 4 mq | |

| 1900/2500Kg | |

| 5800/7900Kg | |

| 8000/11000 Kg | |

| C40 | |

|---|---|

| 2060 mm | |

| 2620 mm | |

| 4150 mm | |

| 500X420 mm | |

| 3960 l | |

| 350 l | |

| 4,5 mq | |

| 2400/3200 Kg | |

| 7500/10000 Kg | |

| 10500/14000 Kg | |

| C50 | |

|---|---|

| 2060 mm | |

| 2620 mm | |

| 4650 mm | |

| 600X450 mm | |

| 4800 l | |

| 400 l | |

| 5,5 mq | |

| 2900/3900 Kg | |

| 9100/12000 Kg | |

| 12500/17000 Kg | |

| C70 | |

|---|---|

| 2060 mm | |

| 2310 mm | |

| 5900 mm | |

| 600X450 mm | |

| 6800 l | |

| 700 l | |

| 8 mq | |

| 4100/5400 Kg | |

| 13000/17700 Kg | |

| 18000/25000 Kg | |

| C80 | |

|---|---|

| 2060 mm | |

| 2360 mm | |

| 5900 mm | |

| 800X580 mm | |

| 7940 l | |

| 700 l | |

| 9 mq | |

| 4800/6300 Kg | |

| 15200/20700 Kg | |

| 21000/29200 Kg | |

| C100 | |

|---|---|

| 2060 mm | |

| 2360 mm | |

| 6000 mm | |

| 800X580 mm | |

| 9480 l | |

| 500 l | |

| 10 mq | |

| 5700/7600 Kg | |

| 18500/25500 Kg | |

| 26000/35000 Kg | |

| C150 | |

|---|---|

| 2600 mm | |

| 2640 mm | |

| 6700 mm | |

| 800X580 mm | |

| 14950 l | |

| 500 l | |

| 12 mq | |

| 9000/12000 Kg | |

| 29000/42000 Kg | |

| 43000/57000 Kg | |

| C250 | |

|---|---|

| 2900 mm | |

| 2720 mm | |

| 9900 mm | |

| 800X580 mm | |

| 24700 l | |

| 750 l | |

| 17 mq | |

| 14800/19800 Kg | |

| 49000/75000 Kg | |

| 77000/94000 Kg | |

| C320 | |

|---|---|

| 2850 mm | |

| 2720 mm | |

| 10100 mm | |

| 800X580 mm | |

| 32100 l | |

| 700 l | |

| 17 mq | |

| 19300/25700 Kg | |

| 64000/100000 Kg | |

| 101000/125000 Kg | |

| C440 | |

|---|---|

| 3200 mm | |

| 3000 mm | |

| 11400 mm | |

| 800X580 mm | |

| 44200 l | |

| 700 l | |

| 17 mq | |

| 26500/35400 Kg | |

| 89000/138500 Kg | |

| 139000/172000 Kg | |

-

Maximum extraction of product thanks to the large draing surface of channels.

-

Structure entirely made of aisi 304 stainless steel.

-

Effective filling through wide loading/unloading hermetic door.

-

Easy way replacement system for a quick and simple maintenance of the membrane.

-

“User friendly” interface with colour touch screen.

-

“Champagne” sequential pressing program with pre-loaded formula according to the oenological “french techniques”.

-

14 pressing programs press totally customazable.

-

Dual control system: automaticl (PLC) / manual.

-

Automated marcs unloading.

- I.A. System on the must tray for smart pressing and overfill prevention.

- Automatic/manual start up system for must pump through level controller on the tray.

- Device for overload control.

- Axial loading with pneumatic valve.

- Remote control panel on pedestal.

- Extension legs.

- Must selecton system.

- Automatic washing system of the draining gutters and tank managed by PLC.

- Larger or double pneumatic airtight door.

- Hopper for loading through door.

- Motorized wheels.

- Inert gas Injection System for carbonic soaking.

- Automatic Inerting of the Press with gas release, with flow meter managed by PLC.

- Inerting of the must tray.

- Cooling jacket (not insulated).

- Polyurethane membrane.

-

New compact and modern design, with attractive lines focused to offer a better functionality for the customer.

-

The frame is made of bent sheet metal and no longer with the profiles.

-

All the folds of the tray body are external to facilitate cleaning.

-

Double removable must slipway available up to C50 model for an easy access and better cleaning.

-

Openable folders from the model C 16. From C 100 to C 440 folders are extractable.

-

Safety sensitive border installed on the openable folders.

-

Safety sensor to prevent the tank rotation if the folders are open.

-

Uniform surface finishing (frame and tank) until the models C 80 obtained by stainless steel grit blasting.

-

New bonnet for engine compartment to cover all internal elements, with total opening for easy and immediate access.

-

Rearranging of all the elements of the engine compartment (compressor, blower, valves, control panel, etc.) to facilitate maintenance operations.

-

N. 4 handles to facilitate handling of the Presses on wheels – until the C 50 model.

-

Remote control with standard manual controls.

-

Proper Height of the Press with usable space between the supporting frame and the walking surface, for conveying marcs through the bins.

-

Analogic pressure gauge placed on the supporting frame;

-

Removable eyebolts.

-

Visible Hooks on the frame for tightening the Press to the truck by means of bands during handling.

-

Small Colored fiberglass domes to identify Puleo brand.

-

Swivel wheels with brake.

-

Must reception tray on wheels.

-

Mobile and tilting slipway.

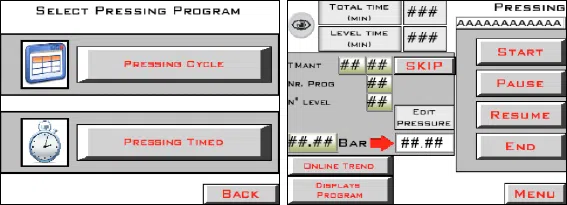

PLC Screen: select pressing program and “press in progress” page with online press chart.