WINERY EQUIPMENT

CONTINUOUS DRAINER

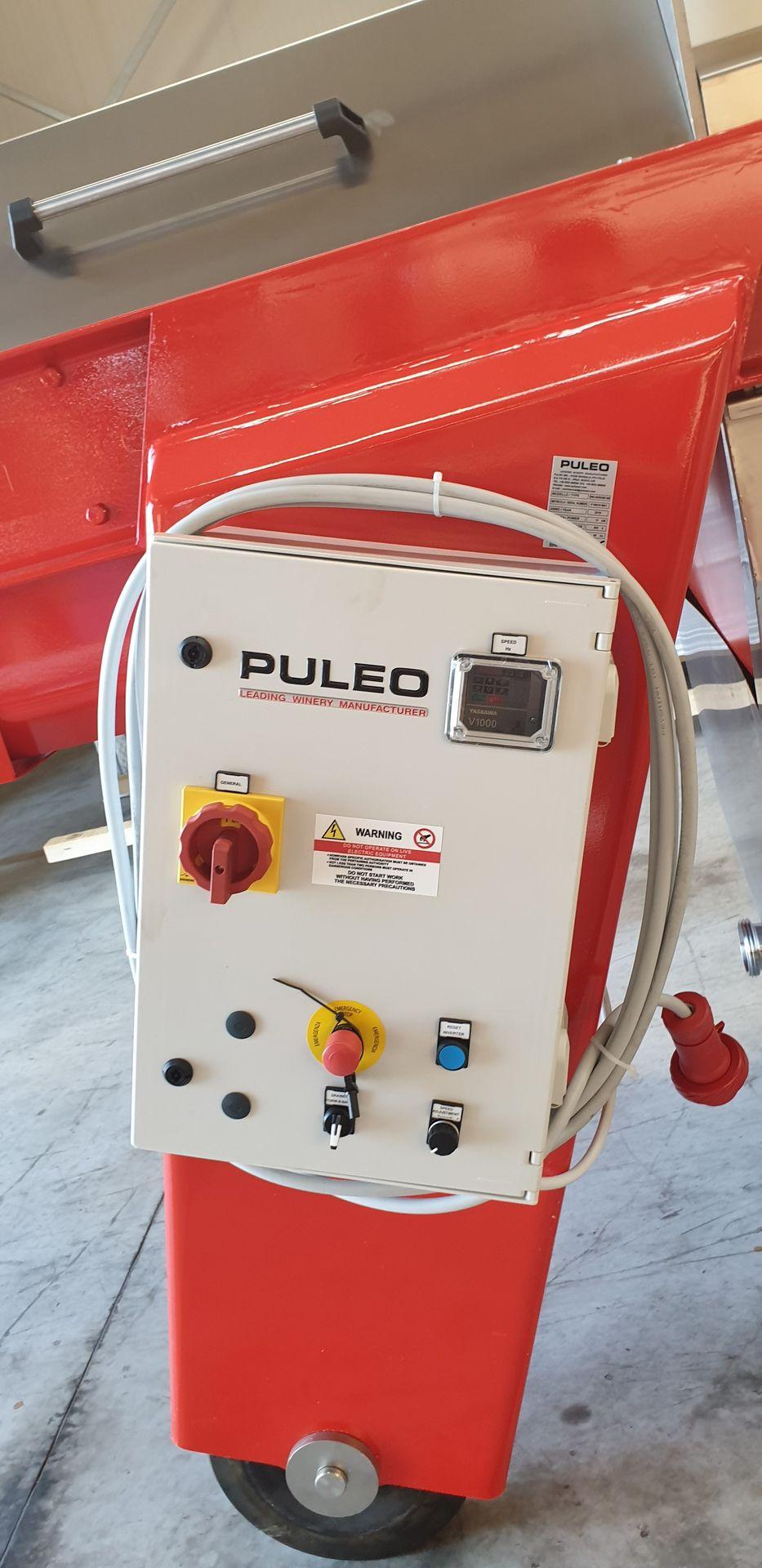

CONTINUOUS LINES - DRAINING PRESS

The continuous drainer is designed to perform the continuous processing of the first draining of fresh crushed grapes or fermented grape marc from autovinificators. This winery equipment guarantees efficient separation of the must, facilitating the winemaking process.

Furthermore, thanks to the inclined position of the oenological machine, the must is easily separated and drained by gravity, without the need for further intervention.

Technical features

- Consisting of a perforated cage inside which rotates a screw with diameters ranging from 400 mm to 900 mm, depending on the model. The screw ensures efficient draining by simple sieving.

- The inclined position of the machine favours the draining of the must and allows automatic gravity draining.

- The percentage of drained must varies from 35% to 50% of the liquid fraction in the processed product.

- The models differ according to the required hourly flow rate to suit different production requirements.

CONTINUOUS DRAINER MODELS

|

| |

ENO-SGROND 450 |

4 kW | 9/10 tons |

ENO-SGROND 620 | 5,5 kW | 12/15 tons |

ENO-SGROND 820 | 7,5 kW | 32/40 tons |

ENO-SGROND 950 | 11 kW | 40/45 tons |

CONTINUOUS DEJUICER MODELS

4 kW

4 kW

9/10 tons

9/10 tons

5,5 kW

5,5 kW

12/15 tons

12/15 tons

7,5 kW

7,5 kW

32/40 tons

32/40 tons

11 kW

11 kW

40/45 tons

40/45 tons