The pressing has the goal to extract the juice from the grapes or crushed grapes in the white wine making PROCESS or the must-wine or wine from fermented grapes after racking in the red wine making PROCESS.

This process must respect the integrity of the solid parts of the grape, avoid the breakage of the grape-seeds, the lacerations of stalks, in case of no de-stemmed grapes, and prevent oxidation.

The pressing of grapes takes place into a holed cylindrical tank where a membrane, inflated by compressed air, exerts a certain pressure towards the product obtaining the liquid fraction extraction.

Mainly designed for the soft pressing of grapes and for the extraction of high quality must, the new Puleo Pneumatic Presses introduce a long series of improving upgrades.

| F16 | 1725 mm | 2240 mm | 3200 mm | 360x460 mm | 1670 l | 300 l | 1000/1300 Kg | 3000/4200 Kg | 4200/5700 Kg | |

| F22 | 1725 mm | 2240 mm | 3700 mm | 880x450 mm | 2170 l | 400 l | 1300/1700 Kg | 4000/5500 Kg | 5500/7600 Kg | |

| F30 | 1950 mm | 2470 mm | 4100 mm | 900x490 mm | 3100 l | 400 l | 1900/2500 Kg | 5800/7900Kg | 8000/11000 Kg | |

| F40 | 2060 mm | 2595 mm | 4150 mm | 500x1000 mm | 3960 l | 350 l | 2400/3200 Kg | 7500/10000 Kg | 10500/14000 Kg | |

| F50 | 2060 mm | 2595 mm | 4650 mm | 500x1000 mm | 4800 l | 400 l | 2900/3900 Kg | 9100/12000 Kg | 12500/17000 Kg | |

| F70 | 2060 mm | 2270 mm | 5900 mm | 600x750 mm | 6800 l | 410 l | 4100/5400 Kg | 13000/17700 Kg | 18000/25000 Kg | |

| F80 | 2060 mm | 2320 mm | 5900 mm | 600X450 mm | 7940 l | 410 l | 4800/6300 Kg | 15200/20700 Kg | 21000/29200 Kg | |

| F100 | 2060 mm | 2320 mm | 6000 mm | 600x750 mm | 9480 l | 500 l | 5700/7600 Kg | 18500/25500 Kg | 26000/35000 Kg | |

| F150 | 2470 mm | 2510 mm | 7000 mm | 700x700 mm | 14950 l | 500 l | 9000/12000 Kg | 29000/42000 Kg | 43000/57000 Kg | |

| F250 | 2740 mm | 2670 mm | 9000 mm | 700x700 mm | 24700 l | 700 l | 14800/19800 Kg | 49000/75000 Kg | 77000/94000 Kg |

| F16 | |

|---|---|

| 1725 mm | |

| 2240 mm | |

| 3200 mm | |

| 360x460 mm | |

| 1670 l | |

| 300 l | |

| 1000/1300 Kg | |

| 3000/4200 Kg | |

| 4200/5700 Kg | |

| F22 | |

|---|---|

| 1725 mm | |

| 2240 mm | |

| 3700 mm | |

| 880x450 mm | |

| 2170 l | |

| 400 l | |

| 1300/1700 Kg | |

| 4000/5500 Kg | |

| 5500/7600 Kg | |

| F30 | |

|---|---|

| 1950 mm | |

| 2470 mm | |

| 4100 mm | |

| 900x490 mm | |

| 3100 l | |

| 400 l | |

| 1900/2500 Kg | |

| 5800/7900Kg | |

| 8000/11000 Kg | |

| F40 | |

|---|---|

| 2060 mm | |

| 2595 mm | |

| 4150 mm | |

| 500x1000 mm | |

| 3960 l | |

| 350 l | |

| 2400/3200 Kg | |

| 7500/10000 Kg | |

| 10500/14000 Kg | |

| F50 | |

|---|---|

| 2060 mm | |

| 2595 mm | |

| 4650 mm | |

| 500x1000 mm | |

| 4800 l | |

| 400 l | |

| 2900/3900 Kg | |

| 9100/12000 Kg | |

| 12500/17000 Kg | |

| F70 | |

|---|---|

| 2060 mm | |

| 2270 mm | |

| 5900 mm | |

| 600x750 mm | |

| 6800 l | |

| 410 l | |

| 4100/5400 Kg | |

| 13000/17700 Kg | |

| 18000/25000 Kg | |

| F80 | |

|---|---|

| 2060 mm | |

| 2320 mm | |

| 5900 mm | |

| 600X450 mm | |

| 7940 l | |

| 410 l | |

| 4800/6300 Kg | |

| 15200/20700 Kg | |

| 21000/29200 Kg | |

| F100 | |

|---|---|

| 2060 mm | |

| 2320 mm | |

| 6000 mm | |

| 600x750 mm | |

| 9480 l | |

| 500 l | |

| 5700/7600 Kg | |

| 18500/25500 Kg | |

| 26000/35000 Kg | |

| F150 | |

|---|---|

| 2470 mm | |

| 2510 mm | |

| 7000 mm | |

| 700x700 mm | |

| 14950 l | |

| 500 l | |

| 9000/12000 Kg | |

| 29000/42000 Kg | |

| 43000/57000 Kg | |

| F250 | |

|---|---|

| 2740 mm | |

| 2670 mm | |

| 9000 mm | |

| 700x700 mm | |

| 24700 l | |

| 700 l | |

| 14800/19800 Kg | |

| 49000/75000 Kg | |

| 77000/94000 Kg | |

- Maximum extraction thanks to the wide draining surface tank.

- Structure entirely made of aisi 304 stainless steel.

- Manual axial load.

- Pneumatic or manual double loading/unloading door.

- Easy way replacement system for a quick and simple maintenance of the membrane.

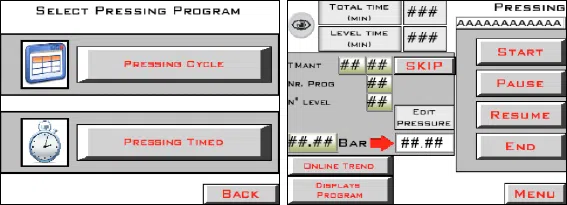

- “User friendly” interface with colour touch screen.

- “Crémant” sequential pressing program with pre loaded formula according to the oenological “french technique”.

- 14 pressing programs totally customizable.

- Dual control system: automatic (PLC) / manual.

- Automated marcs unloading.

- Sistema wine-wise sulla vasca mosto per gestione intelligente della pressatura e protezione antitracimazione.

- Sistema di controllo livello vasca mosto a galleggiante e comando pompa evacuazione.

- Dispositivo per il controllo del sovraccarico.

- Carico assiale con valvola pneumatica.

- Quadro di comando remotato su piedistallo.

- Rialzi per basamento pressa.

- Selezione mosti a due vie con valvole pneumatiche.

- Tramoggia di caricamento uva intera da portella.

- Assistenza remota.

- Impianto di lavaggio esterno del tank.

- Ruote motorizzate.

- Membrana in poliuretano anziché in PVC.

- New compact and modern design, with attractive lines focused to offer a better functionality to the customer.

- The frame is made of bent sheet metal and no longer with profiles.

- All the folds of the tray are external to facilitate cleaning.

- Double removable must slipway available up to F 50 model for an easy access and better cleaning.

- Openable folders from the model F 22.

- Safety sensitive border installed on the openable folders.

- Safety sensor to prevent the tank rotation if the folders are open.

- Uniform surface finishing (frame and tank) up to the model F 80 obtained by stainless steel grit blasting.

- New bonnet for engine compartment to cover all internal elements. Total opening for easy and immediate access.

- Rearranging of all the elements of the engine compartment (compressor, blower, valves, control panel, etc.) to facilitate maintenance operations.

- N. 4 handles to facilitate handling of the Presses on wheels – up to the F 50 model.

- Remote push button panel with standard manual controls.

- Proper Height of the Press with usable space between the supporting frame and the walking surface, for conveying marcs through the bins.

- Analogic pressure gauge placed on the supporting frame.

- Removable eyebolts.

- Visible Hooks on the frame for tightening the Press to the truck by means of bands during handling.

- Small Colored fiberglass domes to identify Puleo brand.

- Swivel wheels with brake.

- Must reception tray on wheels.

PLC Screen: select pressing program and “press in progress” page with online press chart.